Circular Manufacturing at CRF in Italy

Circular Manufacturing at CRF in Italy

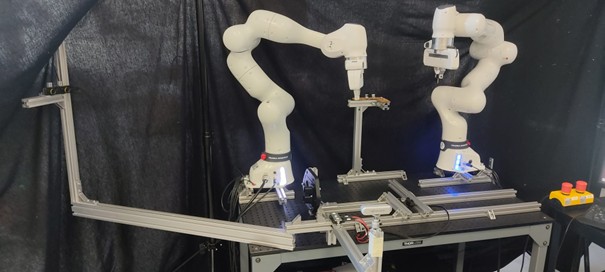

Batteries Assembly-Control-Disassembly in circular manufacturing lines

What is the Use Case about?

In short – it is about the automation of the quality control process in the Batteries Assembly-Control-Disassembly in circular manufacturing lines.

But let us explain further.

This use case, provided by CRF (Stellantis group), is based on a hypothetical circular manufacturing line in the domain of electric vehicle production and recycling.

The task of assembling a battery requires a mix of predetermined sequences, complex cable placing, and tracked operations and it is performed mainly by humans today. In INVERSE, we will use cameras (fixed or on the robot) to track the assembly of batteries and we will build a model for assembly quality and disassembly quality based on this data.

The CRF use case will be based on a sequence of two workstations designed to demonstrate:

1) Assembly tasks with active monitoring

2) Quality proactive monitoring (signaling errors and fixing them if feasible)

3) Autonomous or collaborative disassembly.

Use Case Site

CRF – Centro Ricerche Fiat (Stellantis Group), Orbassano (Italy), with supplementary testing at UNITN (IT) and VTT (FI) integration facilities.

Who is involved?

- Pilot owner: CRF (Stellantis Group)

- INVERSE Partners are involved as core technology partners

Challenges

Which difficulties does the use case want to solve?

The standard approach for quality control in a battery assembly line is to avoid the generation of errors by carefully designing the entire production process with human quality control.

How is this done today? On the shopfloor, the vehicle’s final assembly phases are mainly performed manually, with less than 7% of the operations being automated. There is the complexity of the operations as well as the requirements of flexibility, dexterous manipulation, and improvisation capability.

In a typical circular manufacturing line, the human remains the main actor. Due to the limited transit time (Stellantis has a throughput of up to 1 vehicle/minute), operators often have no time to perform quality control, which is performed at the end of the line for functionality and safety. For critical processes like battery assembly, the quality control is tightly connected to the vehicle safety (a loose screw can generate explosive short circuits) and thus is performed thoroughly on each part.

Objectives

What drives the use case activities?

Remember, the main goal of the use case is the automation of the quality control process.

In order to achieve this in INVERSE we will:

- exploit a new concept where cameras (fixed or on robot) are used to monitor the assembly task sequences.

- build a model of the assembly phases that will be performed and inverted to generate a model of assembly quality (later used in a proactive manner with the possibility to check and solve) and a model of disassembly.

Approach & Solution Developed

INVERSE uses the following approaches and develops the following solutions:

- MoCLE loop (Multi‑modal Continual Learning & Execution): the robot continuously improves from human demonstrations, sensor data and its own experience

- Perception & anomaly detection: vision‑based sequence monitoring, fault detection and confidence estimation

- Neuro‑symbolic planning: links learned skills with symbolic operators for explainable planning and task inversion (assembly → disassembly)

- Human‑centred HRI: intuitive Human‑Factory Interface (HFI) for supervision, teaching and on‑the‑fly adjustments

- Integration for TRL5: common ROS2‑based architecture validated in a realistic industrial setup

Expected Outcomes

The expected outcomes of the activities in this Use Case are:

- Safer, higher‑quality assembly with early defect detection and automatic recovery strategies

- Executable inverse plans for efficient disassembly, enabling repair and high‑yield recycling

- Measurable improvements targeted by project KPIs (e.g., lower failure rates in direct tasks, reduced missed defects during QC)

- Environmental benefits: reduced GHG footprint via reuse and recycling, evidenced by LCA