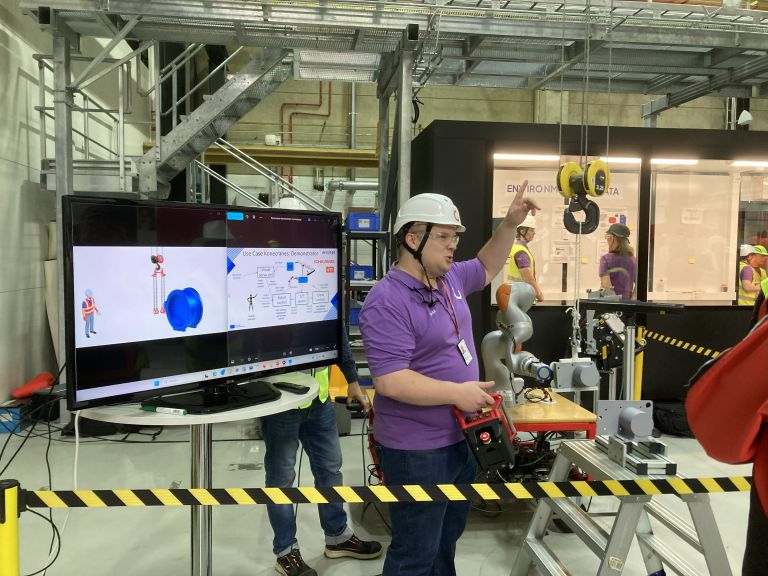

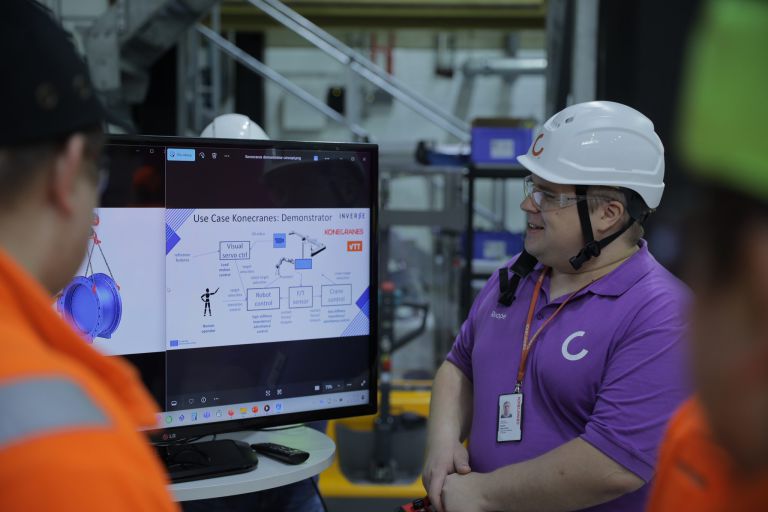

Robot–Crane–Human Interaction at Konecranes

Human–robot support for efficient positioning and reduced risk in short-series production.

What is the Use Case about?

Overhead cranes are widely used in assembly and intralogistics operations, especially in short-series production of large and heavy mechanical engineering products.

This pilot showcases synchronized collaboration between a crane, a robot, and a human operator to handle heavy, bulky components in short‑series production. INVERSE automates lifting‑aid changes, assists precise positioning, and inverts cycles when needed (e.g., to undo an assembly step), improving ergonomics, safety and productivity.

Use Case Site

Konecranes Global in Hyvinkää (Finland), with supplementary integration/testing at UNITN (IT) and VTT (FI).

Who is involved?

- Pilot owner: Konecranes

- INVERSE Partners are involved as core technology partners

Challenges

Which difficulties does the use case want to solve?

The use of Overhead Cranes in assembly and intralogistics operations is not automated today and the current procedure is mainly performed by human workers. It is mentally and physically exhausting, and potentially dangerous for the human worker.

- Overhead cranes normally serve several workstations where they are used to assist in a wide range of tasks, which are difficult to automate because of the weight and size of components to be handled.

- Furthermore, each lifting operation may require component-specific lifting aids and fixing methods. Typically, a significant amount of time is wasted just in fetching the right lifting aids from their storage area.

- Assembly tasks performed with the aid of cranes require accurate component positioning, which is done manually by guiding the components to their locations while operating the crane.

Therefore, the INVERSE framework will improve poor working conditions in a strategic sector like the heavy mechanical industry. Moreover, assembly and disassembly of the axle will demonstrate the usability of INVERSE technology in repair and reuse of gearboxes.

Objectives

What drives the use case activities?

Because the traditional process is dangerous, this use case focuses on improving the productivity and safety of crane operations by introducing a system where work tasks are divided and synchronised between the human operator, crane, and robot, and the tasks can be executed in direct and inverse order.

The process planned to validate INVERSE technologies includes the following steps:

1) Manufacturing Operations Management system, interfaced with HFI, sends the data about the next lifting to the crane

2) The crane drives automatically to storing area of heavy axles

3) The crane lowers the hook and informs a robot about the hook position

4) The robot detaches the current lifting aid from the hook (HRC) and stores it (autonomously)

5) The robot picks the lifting aid specific to the next lifting operation from the storage (autonomously), and attaches it to the hook and to the axle (HRC)

6) The robot acknowledges the tasks done; the operator activates the assembly task from the crane pendant (enriched with HFI)

7) The synchronised human-robot-crane installation of the axle to a gearbox is planned, executed, and monitored

8) The crane lifts the hook, drives autonomously to the gear assembly station, and lowers the hook while the robot accurately positions the axle, and, in case a problem is detected (e.g., wrong mechanical tolerance)

9) The cycle is inverted and the axle is brought back to the starting location.

Approach & Solution Developed

This Use Case utilizes the following approaches and develops the following solutions:

- End‑to‑end orchestration: production data triggers the crane to autonomously move; the robot changes/attaches the correct lifting aid and coordinates with the operator

- Human‑aware planning: neuro‑symbolic task & motion planning integrates human intent recognition, safety constraints and semantic context

- Perception & prediction: scene understanding and operator‑intention cues inform safe, efficient trajectories

- HFI & usability: intuitive interfaces for supervision and hand‑offs; iterative user studies for acceptance and training

- TRL5 integration: modular ROS2‑based stack tested in KC’s pilot environment

Expected Outcomes

The expected outcomes for the Use Case are the follwing:

- Improved safety & ergonomics: fewer risky maneuvers for operators; assistance during heavy handling

- Productivity gains: faster lifting‑aid changes, reduced search time, smoother handling/positioning

- Quality & flexibility: accurate assembly/fit‑up; cycle inversion to handle deviations without damage

- Environmental impact: efficiency gains and LCA‑based guidance for lower energy use in handling operations